- Regular maintenance and repairs: It is important to subject the machine to periodic maintenance and repair processes. This includes lubrication, cleaning, checking drivers, and replacing worn-out parts.

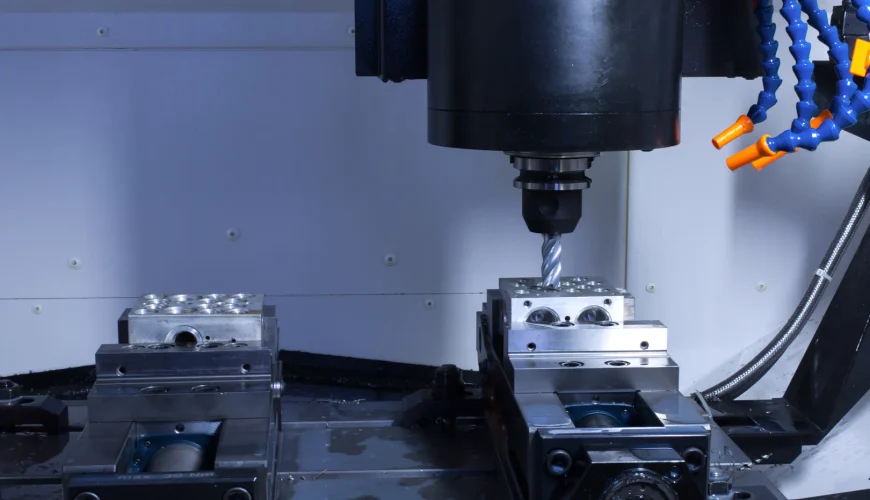

Good operating practices: Using and operating CNC machines correctly is crucial. Users should carefully follow machine instructions and pay attention to factors such as proper cutting speeds, the use of cooling systems, and selecting the right cutting tools.

Updates and upgrades: Keeping track of updates released by the manufacturer for the machine and implementing necessary upgrades can enhance performance and extend the usage time.

Spare parts inventory: Over time, worn-out parts may need to be replaced in CNC machines. Maintaining an inventory of necessary spare parts allows for quick intervention and can impact the usage time.

Training and Competence: It is important for operators and maintenance personnel to receive proper training and continuously improve their skills. This ensures effective use of the machines and quick resolution of potential issues.

These methods can be effective in extending the usage time of CNC machines. Factors such as regular maintenance, proper usage, monitoring updates, maintaining spare parts inventory, and training contribute to the machine’s ability to operate efficiently for a longer period.